Safety stock is an additional quantity held in inventory in order to reduce the risk that an item will be out of stock when a customer places an order. This acts as a buffer in case demand is greater than planned or the supplier is unable to deliver additional units at the expected time.

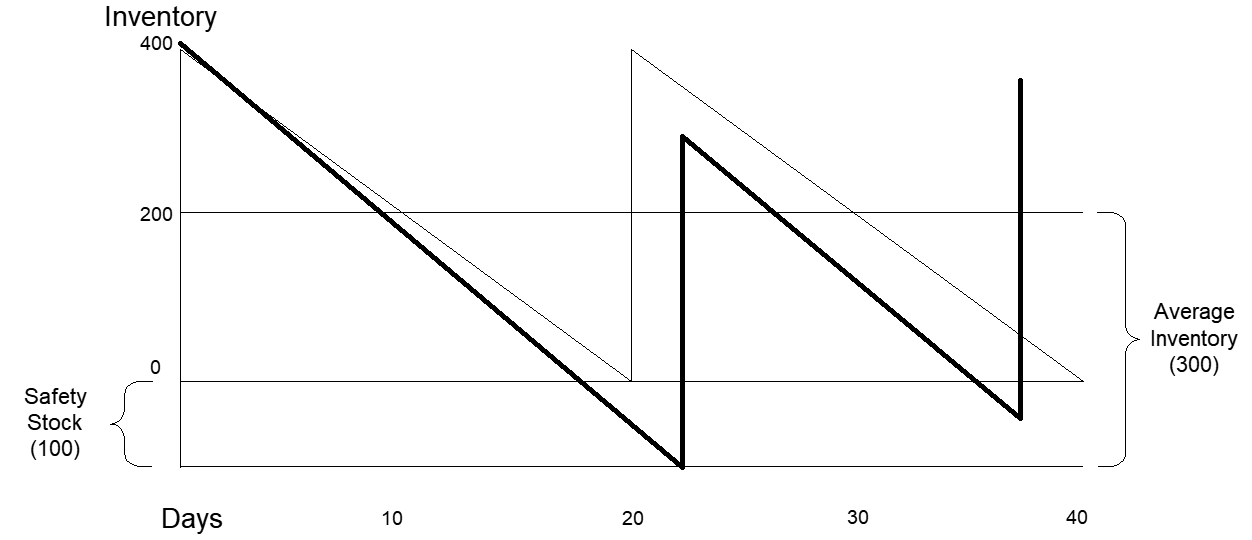

Over time, inventory goes up and down. As customer order shipments are made inventory transactions subtract the ship quantity from the quantity on hand. When production is made or goods received into the warehouse the quantity on hand goes up. This up/down cycle can be thought of as a ‘saw tooth’. Except it’s never as neat and tidy as this.

Cycle stock can be calculated as ‘Demand during Lead Time’, or if we make or buy product once a period I should have at least enough to last until the next order arrives. One way to do this is to first determine the replenishment time (RT) or the time between orders. For high volume products we may make the product every month, so the RT would be 30 days or 4 weeks or 1 month.

Next we need to know the consumption, sales forecast, or historical shipments and then calculate the average demand during the replenishment period.

AD = average demand, RT = replenishment time, or campaign interval, or period between receipts.

In this example we receive 400 every period. Our stock on hand goes from 400 down to zero just as the next resupply arrives. The average inventory isn’t 400 or 0, it’s 200. When there are many products being received and issued every day some are near max, some are near zero, but the average for all products is ½ (max – min).

But this is still too simple. Consumption (issue from stock, or shipments) is never exactly smooth, sometime higher or lower than planned. Sometime resupply is earlier or later than planned or in different quantity than planned. So we have two types of supply & demand variation to think about. We need safety stock and safety lead time to protect our customers from variation in supply and demand.

In this example we have 100 in safety stock. If everything were perfect inventory would cycle between 500 and 100. We keep 100 just in case production is late or customer demand is higher than expected.

Demand can come in faster or in greater quantity than we had planned (red dashed line). If we can’t get the product resupplied sooner we have a period of stock out or back order.

With safety stock we can try to prevent back orders or stock outs.

We dip in to safety stock when resupply is late.

Putting this all together we get …

Example:

Demand Safety Stock can be calculated, but first we need to look at some statistics. Here is graph of weekly shipments for CARILATUDE 350MG for the period of 1/1/2012 to 12/31/2012.

Here are some descriptive statistics:

Total shipped = 1,066,772

Weekly Average = 20,449

Max Week = 61,776

Min Week = 6,360

Weekly Standard Deviation = 8,883

Coefficient of Variation = Std Dev/Average = 0.43

How much inventory should we keep for this product? Do we want to have enough to cover the two big spikes or is it OK to go on back order for a week or two? Before we can answer these questions we need to know a few things.

- How often do we receive this product in to stock? If we make the product once a month, then we need to have enough in stock to last for a month plus any uptick in demand and some more to cover if production is late on the next run.

- What service level does management want to achieve? You would need infinite inventory to cover all possible customer demand and supply issues.

We don’t have enough money or warehouse space to hold all the stock we might want. So we have to accept some level of stock out or back order. Where we carry more stock than we need we have consumed raw materials, production capacity, machine time, labor that could have been used to make other products. When we don’t have enough stock on hand we are often forced to change the schedule and make product earlier than planned, and this means other products get pushed out. The trick is to set just the right level of target inventory with not too much safety stock.

To set Safety Stock we can consider three types of additional inventory based on the source of variation:

Demand Safety – customer demand can come in greater volume than expected and deplete inventory before the next planned replenishment (raw material or production run).

Supply Leadtime – production can be late due to machine breakdown, labor availability, scheduling changes, lost batch, or get hung up for a variety of reasons

Murphy – unpredictable circumstances that management might want to hedge.

There is also seasonality and planned stock builds, but we aren’t addressing those here.

Demand Safety is based on service level and demand standard deviation.

The safety factor is based on the service level management is trying to achieve.

| Service Level % | Safety Factor |

| 60 | 0.26 |

| 70 | 0.52 |

| 75 | 0.77 |

| 80 | 0.84 |

| 85 | 1.04 |

| 90 | 1.28 |

| 92.5 | 1.44 |

| 95 | 1.65 |

| 97.5 | 1.96 |

| 98 | 2.05 |

| 99 | 2.33 |

| 99.5 | 2.58 |

| 99.9 | 3.08 |

When we calculate, for each product, the weekly shipment historical margin contribution average, standard deviations, and Cv and then graph the average vs Cv for each product we get the following Demand Segmentation graph …

Here we see that there are many product with low volume that are very unpredictable (Cv > 1.0) unfortunately we may have to keep stock for these products. Because the history shows that shipments are erratic we may have to carry a lot of inventory to be able to cover the unpredictable demand. Fortunately most of the high volume products are predictable, but some are on the edge of being noisy and so we may have to carry a large amount of safety stock for these too.