Maslow’s hammer, or a golden hammer is an over-reliance on a familiar tool; as Abraham Maslow said in 1969 in A Psychology of Science, “It is tempting, if the only tool you have is a hammer, to treat everything as if it were a nail.” So, must every product in every business segment be set up in a one piece flow cell? Or put on kanban with an heijunka to smooth demand? Or run on a rate-based assembly line? Certainly not! One size rarely fits all. But how to know which techniques make sense?

One place to start is to look at customer demand. All lean practitioners know about Takt Time, or the customer drum beat, that is used to match the pace of an operation with customer demand. Takt Time is calculated as Available Time/Demand, and is by definition a ratio of averages. But customer demand is anything but average, and so we need to understand the variation or range of demand placed on our process.

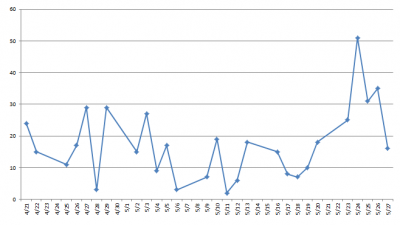

Here’s an example …

To build a demand profile take the following steps:

To build a demand profile take the following steps:

- Pick a product, product family, customer, customer-item pair, or business unit of interest.

- Determine an appropriate time unit – hourly, daily, monthly.

- Gather the true demand as best you can. Be careful about using promise dates instead of requested dates, and be doubly cautious of schedules which are often smoothed, filtered, or otherwise manipulated.

- Create the graph or time series plot as above.

- Now calculate some simple descriptive statistics – range, minimum, maximum, standard deviation, etc. In this example the average is 17 with a range of 49 and a standard deviation of 11.

What can we conclude? Should we design our operations control around a demand rate of 17 a day? Is the variation in demand something we can deal with? How?