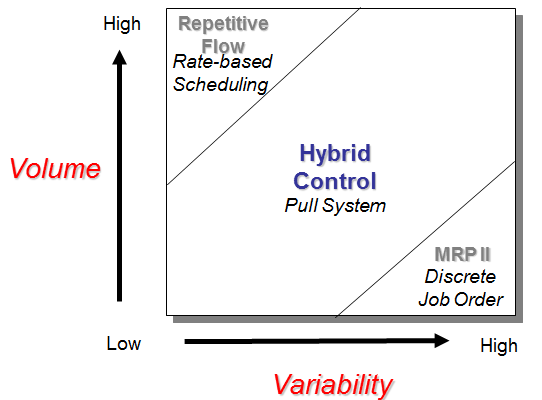

Determining an appropriate production model starts with Demand Profile and Demand Segmentation. High volume low variability items, and low volume high variability items behave very differently. How to decide if a particular product is a candidate for a one piece flow cell or a craftsmen job bench? Look to the coefficient of variation for a clue.

Type 1 – Rate-base or Just-in-time

- forecasting of the flow rate or takt time

- RCCP – rough cut capacity planning to monitor impact of mix and volume on pace maker operation

- produce to rate (or TAKT) vs discrete order or customer pull

- demand flow vs time-phased requirements planning

- maintain flow priority and timing

- no detailed Capacity Requirements Planning required

- no or minimal shop order launch or inventory transactions

- highly visual and standardized shop floor control

- “one-piece” flow, zero inventory, standard WIP – work-in-process

- seamless flow/pull of material

- Dynamic cycle time (Little’s Law)

Type 2 – Pull

- combination of discrete forecasting and/or demand rate-based forecasting

- MRP planning — pull Kanban, Heijunka visual shop floor control

- RCCP, but no detailed CRP

- flat Bills Of Materials

- more cellular manufacturing

- point-of-use vs. central stores

- inventory is strategic: standard inventory, time-based replenishment, pull based on consumption vs. push based on demand

- based on statistically balanced rate, build to level-loaded demand with calculated standard inventory buffers

Type 3 – Push or Job Shop Discrete

- discrete requirements planning (firm orders and long range forecast)

- Rough Cut Capacity Plan

- time phasing of requirements

- application of order policies: lead time, safety stock & time

- Capacity Requirements Planning

- MRP shop order launch & order maintenance (message filters and “noise management”)

- ability to aggregate disparate requirements across multiple products by work center, supplier, product

- central stores of inventory

- multi-level inventory: stores, pick, kit, move, queue

- batch processing

- demand leveling difficult and uneconomical

2 thoughts on “Replenishment Strategies”

Do you have a reference that digs into this segmentation method more?

Try

https://www.resourcesystemsconsulting.com/blog/demand-segmentation-one-size-fits-none/

Manufacturing for Survival – Blair Williams

Lean Sigma: A Practitioner’s Guide – Ian Wedgewood

http://www.tbmcg.com/misc_assets/DemandSegmentation_TBM_CarlisleTW.pdf

http://www.supplychainsegmentation.com/index